Simple Tips To Effortlessly Preventing Hoop Burn In Machine Embroidery

1.What Is Embroidery Hoops Burn?

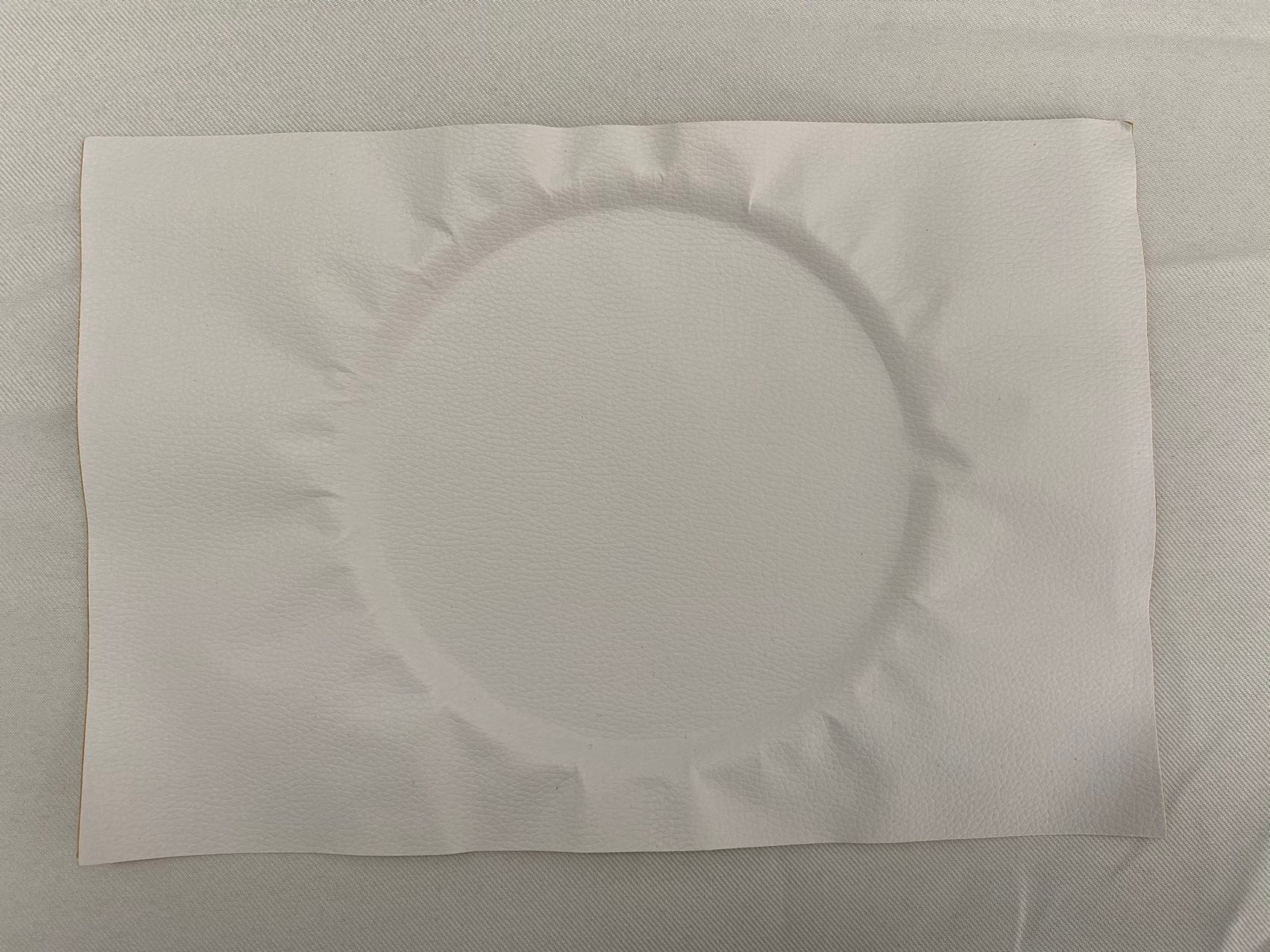

Embroidery hoops burn, also known as hoop burn or hoop rash by many embroiderers, refers to a temporary or permanent marks left on sensitive fabrics caused by the friction of the embroidery frame. It is a common issue faced by those who enjoy embroidery or cross-stitching, especially when working with tightly stretched fabric.

The hoop burn occurs when the same fabric (like as: shirts) is tightly secured between the embroidery frame's inner ring and outer ring, causing friction on the fabric. This friction can result in a visible mark or indentation on the fabric, which can be challenging to remove, especially in delicate fabrics.

While the marks can be unsightly, they usually do not affect the final result of the embroidery project. However, it is always a good idea to prevent hoop burn by hooping method and loosening the hoop tension, hooped properly,regularly moving the hoop around to distribute the pressure, or using a same fabric/garment barrier, such as a piece of felt or muslin, between the fabric/garment and the hoop.

Magnetic MaggieFrame (Use code DAVIDZHAO002 for $$ off) can help reduce hoop burn or marks on fabric when compared to traditional embroidery hoops. Hoop burn or marks occur when the fabric is pressed too tightly against the hoop, causing an indentation or impression on the fabric. Traditional embroidery hoops hold the fabric in place with pressure from the hoop's outer ring and an inner hoop, which can cause hoop burn or marks, especially if the fabric is left in the hoop for an extended period of time.

2.What Fabrics Are Affected By Embroidery Hoop Burn?

Embroidery hoops burn can affect a variety of fabrics like as garment, but it is more likely to occur on delicate or synthetic fabrics, such as:

Satin: Satin fabrics are often used in formal wear, but they are also delicate and prone to hoop burn due to their smooth surface and light weight.

Silk: Silk is a luxurious and delicate fabric that is often used for high-end clothing and accessories. However, its fine fibers are easily damaged by the friction of the embroidery hooping.

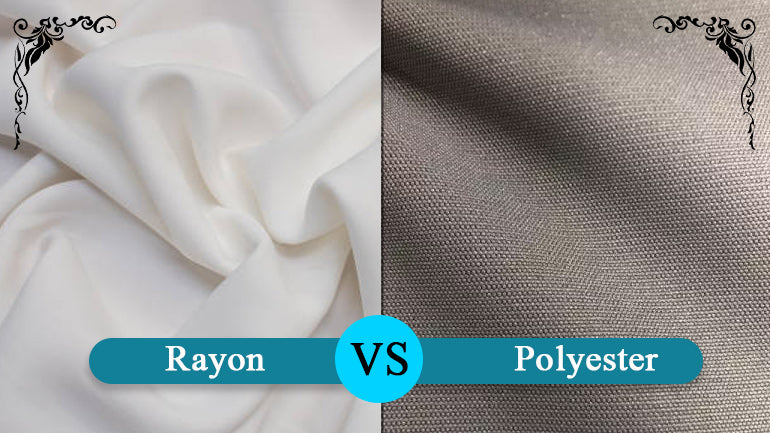

Polyester: Many modern fabrics are made of synthetic materials like polyester. These fabrics are lightweight and durable, but they are also susceptible to hoop burn due to the smoothness of the fibers.

Organza: Organza is a sheer, lightweight fabric that is often used in bridal wear and formal dresses. It is especially prone to hoop burn due to its delicate nature.

Rayon: Rayon is a popular fabric for embroidery, but it is also vulnerable to hoop burn due to its smooth surface and lightweight nature.Garment like velvet are usually difficult to hoop and require other alternative fixing methods, otherwise it cannot be restored to its original state.

It's important to note that any fabric/garment can be affected by embroidery hoops burn if the hoop is too tight or if it rubs against the fabric excessively during stitching. To avoid hoop burn, be sure to use proper hooping techniques and choose the right stabilizer for the fabric you are working with.

3.How Can you Remove And Fixing Hoop Burn In Machine Embroidery?

many embroiderers frequently find hoop burn on the fabric and asked Solutions to get rid of it,If you have already experienced fix hoop burn in maching embroidery, there are several methods you can take to remove and fix it follow:- Remove hoop burn: If the hoop burn is minor, you may be able to remove it by gently rub the affected area with a clean, white eraser or a soft-bristled brush or lint brush. For more severe hoop burn, you may need to use a fabric-safe stain remover, such as a laundry stain remover, to lift the discoloration.

- Re-stabilize the fabric: Once you fix hoop burn, you will need to re-stabilize the fabric to prevent further damage. You can do this by adding a layer of stabilizer to the back of the fabric, or by using a spray starch or stabilizing spray to reinforce the fibers and protect the fabric during stitching.

- Adjust hoop tension: Check the tension of your embroidery hooping to ensure it is properly adjusted. If the hoop is too tight, it may cause dreaded hoop burn. Loosen the tension slightly and test the fabric to see if it helps prevent future hoop burn.

- Change your embroidery technique: If you are experiencing frequent dreaded hoop burn, you may need to adjust your embroidery technique. Consider using a different type of stabilizer, adjusting the speed of your machine, or using a smaller hoop to reduce friction on the fabric.

- Avoid and fix hoop burn in the future: To avoid hoop burn in the future, always use a high-quality embroidery frame, use a backing material, and use designs with minimal stitching. Additionally, be sure to adjust the hoop tension correctly and avoid excessive rubbing or friction during stitching.

By following these steps, you can remove hoop burn in machining embroidery and prevent it from happening again in the future.

4.How To Prevent And Fix Hoop Burn In Machine Embroidery?

Hoop Marks is a common problem in machining embroidery that can occur when the embroidery hooping rubs against the fabric stitch. This can cause the fabric to become stretched, distorted or discolored. Here are some tips to help prevent and avoid dreaded hoop burn in machining embroidery:

-

Use a backing material: Using a stabilizer or backing material can help protect the fabric from being damaged by the embroidery hooped. Choose a backing material that is appropriate for the type of fabric you are using.

-

Choose the right hoop size: Choose a hoop size that is appropriate for the size of your design and fabric. If the smallest hoop size, the fabric will be stretched and may become distorted. If the biggest hoop size, the fabric may not be held securely in place.

-

Adjust hoop tension: Make sure the hoop tension is adjusted correctly to hold the fabric firmly without distorting it. The tension should be tight enough to hold the fabric in place but not so tight that it causes the fabric to stretch.

-

Use a top-quality frame: Invest in a high-quality embroidery hoop that is designed to grip the fabric firmly without causing damage. A good quality frame will also hold the fabric securely in place and prevent it from slipping.

-

Use a hoop guard: A hoop guard is a plastic or silicone cover that fits over the embroidery frame and prevents it from rubbing against the fabric. This can help prevent hoop burn and keep the fabric looking good.

-

Use a design with minimal stitched: Designs with too much stitching can cause excessive friction between the hoop and the fabric, leading to hoop burn. Opt for a design that has minimal stitched or simplify your design to reduce the amount of stitching required.

By following these tips, you can prevent and avoid hoop burn in machine embroidery, ensuring that your projects look their best.

5.How Do You Get Hoop Marks Out of Cross Stitch?

To remove hoop marks from cross stitch, you can follow these steps:

-

First, remove the cross stitch from the hoop if it is still in the hoop.

-

Gently press the fabric around the hoop mark to see if it will lift on its own. Sometimes, this is enough to remove the hoop mark.

-

If the hoop mark persists, try lightly steaming the fabric. You can use a steamer or hold the fabric over a pot of boiling water for a few seconds. Be careful not to burn yourself or the fabric.

-

If the steaming doesn't work, try gently rubbing the hoop mark with a clean, white cloth dampened with water. You can also try using a mild soap or fabric stain remover.

-

If the hoop mark still won't come out, you can try soaking the fabric in a solution of warm water and a small amount of laundry detergent or stain remover for 30 minutes. Be sure to rinse the fabric thoroughly with clean water and allow it to air dry.

It's important to always test any cleaning solution on a small, inconspicuous area of the fabric first to make sure it doesn't cause any damage or discoloration. Additionally, always follow the care instructions for your specific type of fabric.

6. MaggieFrame For Industrial Embroidery Machine Embroidery Work

6.1 What Is Maggie Frame?

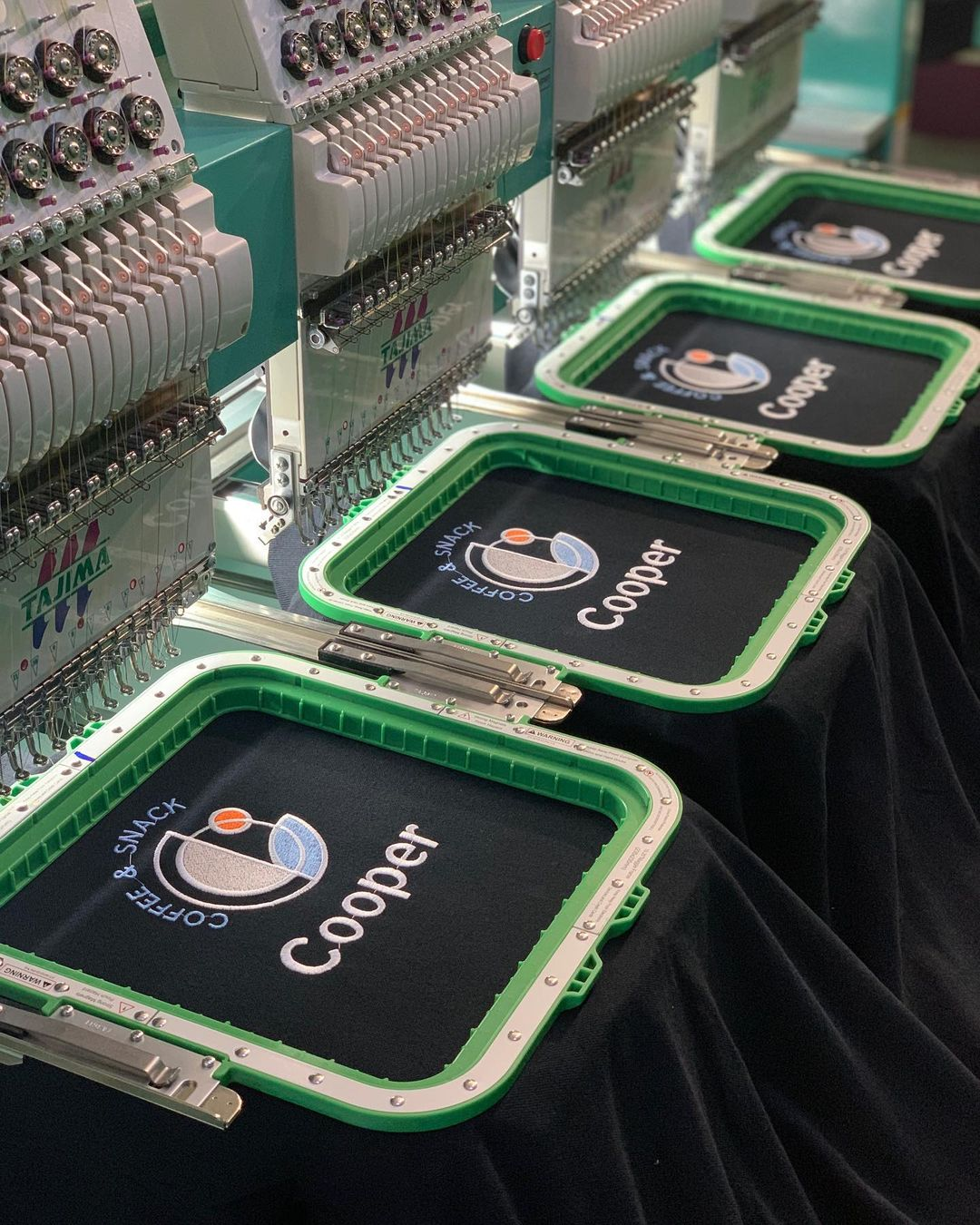

Maggie Frame is a type of magnetic embroidery hoop designed for use with computerized embroidery machines. Unlike traditional embroidery hoops that use tension to hold the fabric in place, Maggie Frame uses a magnetic frame that securely holds the fabric in place without leaving hoop burn or distortion. The frame consists of two magnetic bars that are placed on either side of the fabric and are held together by a strong magnetic force.

6.2 What are Maggie Frame Size?

95x95 mm / 3.8x3.8 inch,100x325 mm / 4x12.8 inch,130x130 mm / 5.1x5.1 inch,150x205 mm / 5.9x8.1 inch,165x165 mm / 6.5x6.5 inch,175x175 mm / 6.9x6.9 inch,195x70 mm / 7.7x2.8 inch,215x225 mm / 8.5x9 inch,195x315 mm / 7.7x12.4 inch,220x125 mm / 8.7x4.9 inch,240x240 mm / 9.5x9.5 inch,265x315 mm / 10.5x12.4 inch,325x105 mm / 12.8x4.1 inch,315x395 mm / 12.4x15.5 inch,435x395 mm / 17.1x15.5 inch (Note: The embroidery size is about 2cm smaller than the Hoop Inside Dimension)

6.3 Wha's Brand Machine Maggie Frame Can Use?

Maggie Frame can fit for different Brand Machine following: Brother(PR&VR/Babylock)/Tajima/Happy/SWF/Ricoma/Barudan/ZSK/Meclo/Janome/Elna/BAI/Fuwei/yuemei/Holiauma/Feiya/Promaker/Fortever/Yeshi and other Chinse Brand Machine.

6.4 Why the Smallest Hoop?

In some cases, a smaller magnetic hoop may be preferred if the design is small or intricate, or if the fabric being used is delicate or difficult to handle. However, larger hoops may be used for larger designs or thicker fabrics. Ultimately, the size of the magnetic hoop would depend on the specific needs and preferences of the user.

6.6 MaggieFrame Fit For Industrial Embroidery Machine Embroidery Work Well

Using MaggieFrame with industrial embroidery machines offers several benefits, such as:

1) Time savings: MaggieFrame's magnetic hooping technology enables quick and easy hooping of fabric, which can save significant time in the embroidery process.

2) Improved accuracy: With the secure hold of MaggieFrame, fabrics are less likely to shift or move during the embroidery process, resulting in greater accuracy and quality in the finished product.

3) Versatility: MaggieFrame's magnetic hoop technology allows for hooping of a wide variety of fabrics and materials, including thick or delicate fabrics, making it a versatile option for industrial embroidery projects.

4) Ease of use: MaggieFrame is easy to use and requires minimal effort for hooping, which can be especially helpful for large-scale or repetitive embroidery projects.

In conclusion, MaggieFrame is a reliable and effective tool for industrial embroidery projects, providing time savings, improved accuracy, versatility, and ease of use.

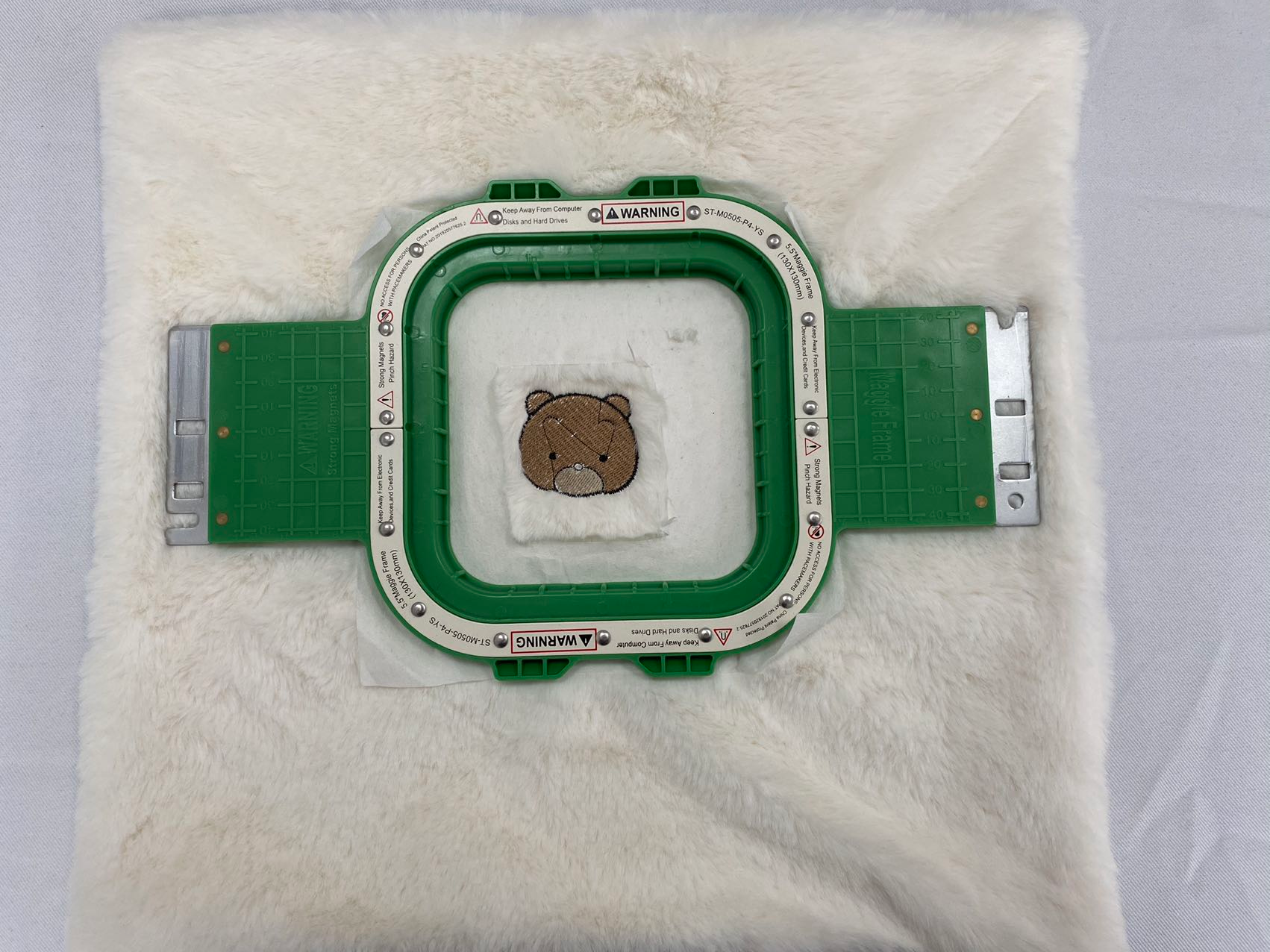

7. How To Use MaggieFrame Floating In Machine Embroidery?

The floating method in machine embroidery refers to the technique of using a stabilizer on top of the fabric being embroidered, rather than hooping the fabric and the stabilizer together. This method can be useful in several different situations, such as when working with delicate or stretchy fabrics, embroidering over existing designs, or creating designs with open areas.

To use the floating method with MaggieFrame magnetic frame, you will need a water-soluble or cutaway stabilizer, a temporary spray adhesive, and a hoop large enough to hold the stabilizer. Here's how to do it:

1) Spray a light coat of temporary adhesive onto the wrong side of the fabric.

2) Lay the fabric onto the stabilizer and smooth it out.

3 Place the MaggieFrame hoop over the fabric and stabilizer, making sure to center the design.

4) Tighten the hoop gently, being careful not to stretch the fabric.

5) Embroider the design as usual.

6) After embroidering, remove loose the hoop and carefully cut away the excess stabilizer.

MaggieFrame magnetic hoop can be a convenient and effective tool for the float method in machine embroidery, making it easier to hoop and re-hoop fabrics and helping to prevent fabric distortion.

8. How To Use MaggieFrame Masking Fabrics In Machine Embroidery?

Masking fabrics in machine embroidery refers to the process of covering certain areas of the fabric with a masking material to protect them from the embroidery stitches. This can be useful when you want to embroider a design that includes open areas or negative space, or when you want to embroider over an existing design or pattern on the fabric.

To mask fabrics with MaggieFrame magnetic hoop, you will need a masking material such as water-soluble stabilizer or masking film, a temporary spray adhesive, and a pair of scissors. Here's how to do it:

1) Cut a piece of masking material large enough to cover the area you want to protect.

2) Spray a light coat of temporary adhesive onto the wrong side of the fabric.

3) Lay the masking material over the area you want to protect, and smooth it out.

4) Place the MaggieFrame hoop over the fabric and masking material, making sure to center the design.

5) Tighten the hoop gently, being careful not to stretch the fabric.

6) Embroider the design as usual, making sure to avoid embroidering over the masking material.

7) After embroidering, remove the hoop and carefully cut away the excess masking material.

MaggieFrame magnetic hoop can be a useful tool for masking fabric in machine embroidery, allowing you to create intricate designs with open areas or to embroider over existing patterns or designs on the fabric. Just be sure to use a light touch when hooping and to use a temporary adhesive that won't leave any residue on the fabric.

9.Conclusion:

Hoop burn is the frustrating shiny marks on a piece of fabric that has been hooped using compression hoops with a tension screw.To prevent and remove hoop burn of fabric when using MaggieFrame with hooping station,Off course, it is important to use the appropriate size of embroidery hooping for the same fabric being worked on, and to use a low heat setting on the embroidery machine. It is also a good idea to use a pull and pressing cloth or a piece of scrap fabric between the hoop and the fabric being embroidered to protect the fabric from heat and pressure. If fabric burn does occur, it may be possible to remove it by gently steaming the affected area, applying heat, using a fabric shaver, or applying a fabric conditioner. In severe cases, it may be necessary to cut away the affected area and cover the hole with a patch or appliqué. By following these tips and techniques, you can let fabric burn disappear and protect your fabrics while embroidering with MaggieFrame and hooping station for a new project.